Cell design, early-stage battery development, cell topopology, operating strategy, fast charging… The optimization of all these points ends up in the ‚digital battery‘. Modelling is such a powerful tool helping to reduce a lot of measuring time and costs. The high dynamics of battery technology development requires advanced cell and battery models.

ion+twin is specialized in cell and battery modelling. We offer custemized model frameworks as well as cell and battery optimizations in the mentioned fields via simulations.

We can outline our expertise by publications and presentations in reputable journals and conferences. ion+twin is an expert in the following fields:

3D cell modeling

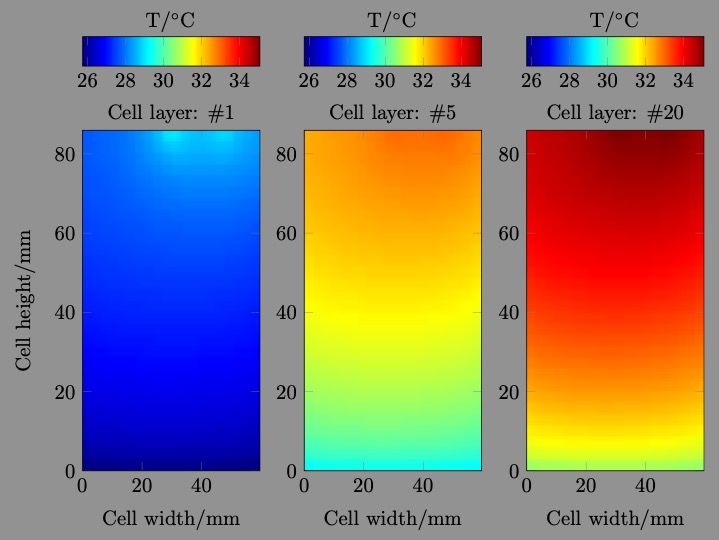

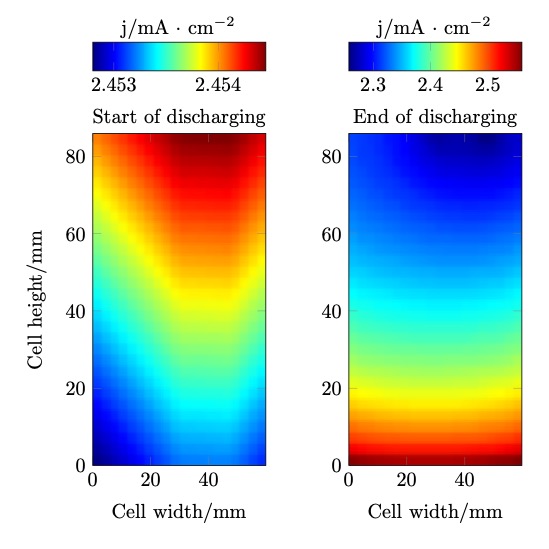

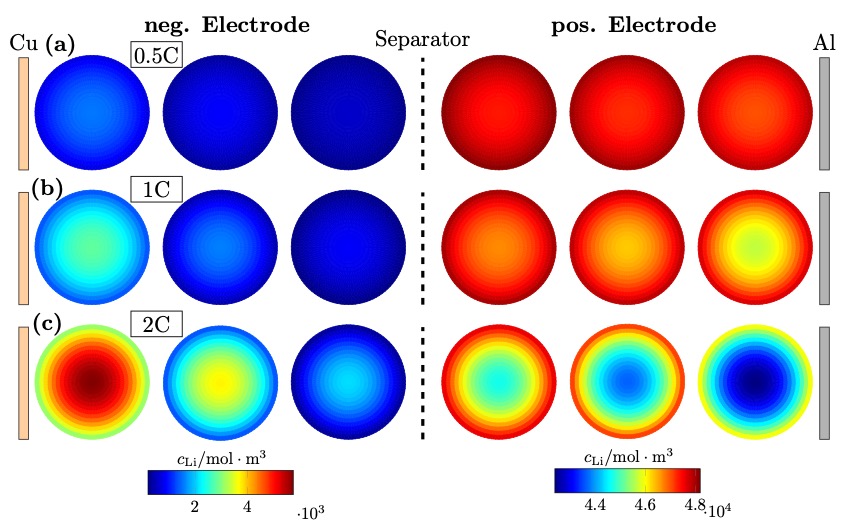

Three-dimensional state resolution of a lithium-ion cell via a Finite Element Model (FEM) is a common tool for cell/battery design evaluation and optimization. In combination with field data analysis these models can be used to realize a digital monitoring of the battery. This enables an early detection of failures, adjustment of operating windows if necessary, or support the recycling/reuse process. It is mostly used to determine the current density, temperature and potential distribution within a lithium-ion cell in dependence of the tab alignment and number of tabs. But also, the influences of the cooling and operating strategy as well as the cell geometry can be evaluated and optimized via FEM.

ion+twin offers customized FEM simulations to evaluate the current density, temperature and potential distribution within a cell. Using this data, ion+twin can optimize the cell design and operation in terms of degradation and provide an analysis of local aging phenomena.

Current density distribution:

Li-concentration within electrode particles and versus electrode thickness:

monte-carlo simulation

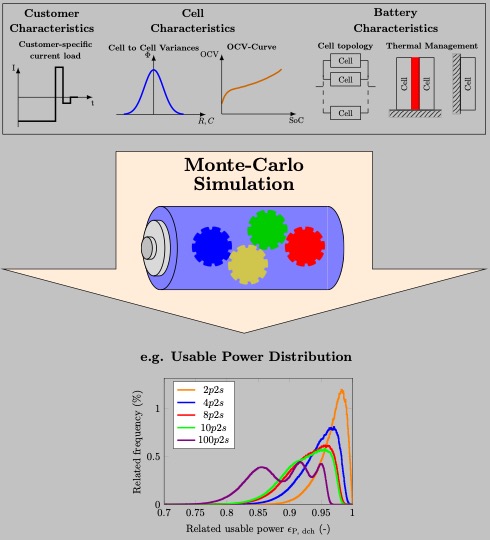

How can cell-to-cell variations or customer-specific load profiles be accounted in battery engineering? Easy, worst-case estimation …

Don’t give away potentials, use the expertise of ion+twin instead! One of the most popular and powerful tools to solve statistical problems are Monte Carlo simulations. This method enables, among other things, to evaluate the effects of manufacturing-related cell-to-cell variations on battery performance in dependence of the cell topology or the driving profile. Based on this analysis, ion+twin optimizes the design and the operating window of your battery.

Stay in touch

Contact or follow us: